A F Connell Ltd undertook the mechanical, electrical and plumbing services for the new Boeing AMRC Factory based in Sheffield.

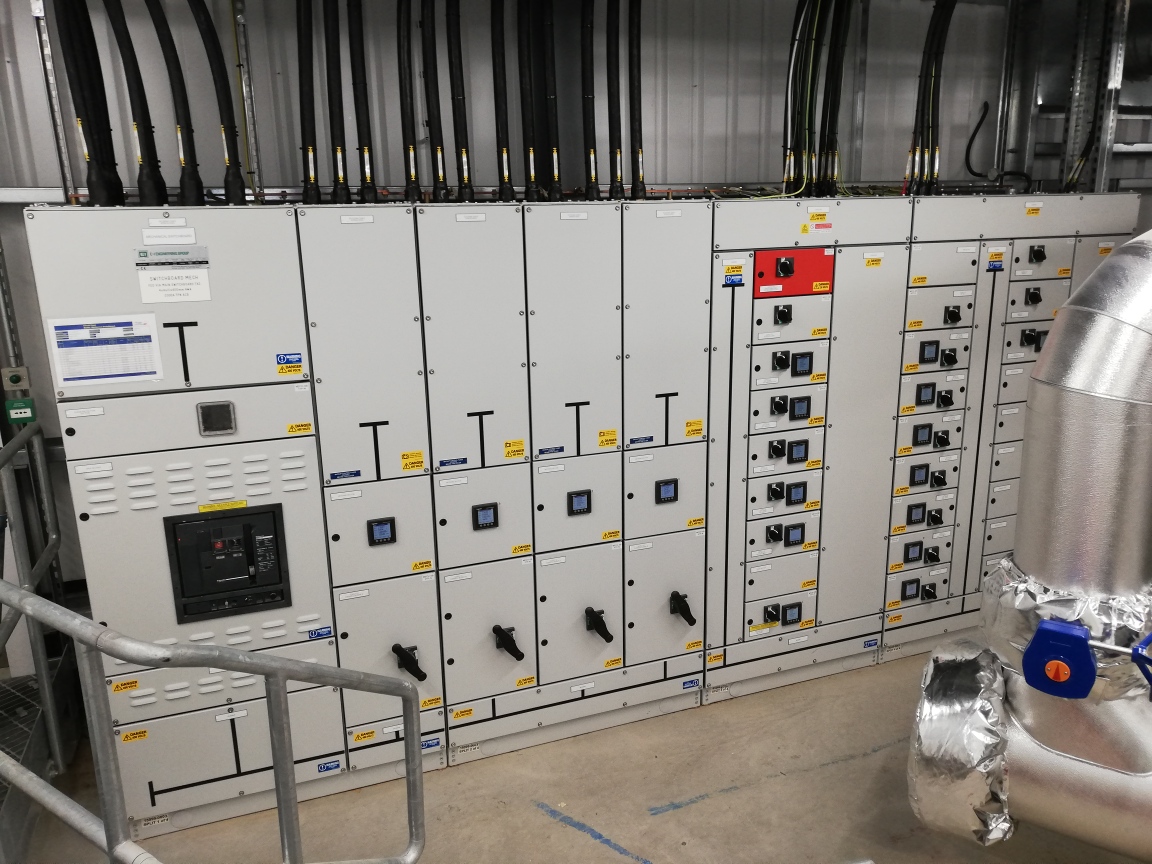

The works comprised of a new electrical substation, 2MVA standby generator, heating, cooling, ventilation and domestic hot and cold water services to the new 2 storey office block and machine hall.

Heating is generated in the plantroom via 3No. gas fired boilers, which serves a 400dia LPHW header which then provides heating to various heating circuits.

Cooling is provided by 2No. external chillers located within the external compound. The heating and cooling to the office block was provided by 4-pipe fan coil units located within the raised access floor. Below ground ductwork and floor mounted supply diffusers distribute the conditioned air to the office area.

The main machine hall is conditioned via air handling units which come with heating and chilled water coils. 1000dia ductwork is distributed at high level, complete with with high velocity supply nozzles to direct the conditioned air into the machine hall.

Ventilation to the office block comprises of a central air handling unit located within the plantroom. Supply & extract ductwork is distributed within the raised access floor to serve the floor mounted fan coil units.

Electrical supplies to production machinery were provided. Specialist services included BMS, fire alarm & detection, CCTV and security systems.